Dry blasting

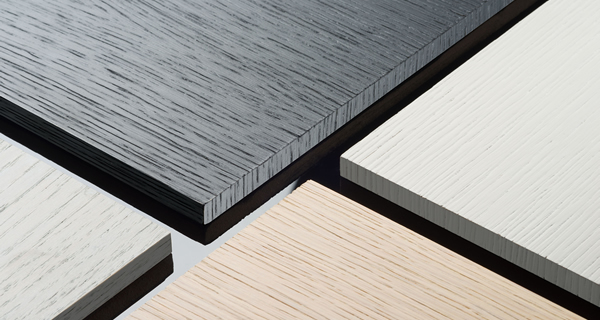

With air erasers, we breathe new life into older furniture at HQcoating. We usually apply the dry blasting technique on wood and veneers. Air stripping can be compared to sandblasting, but more durable. Less hard too, hence the name erasers. We clean the top layer of your wooden, metal or stone object using a ceramic grit under low pressure. Because we work with a maximum of 2 to 4 bar, we remove the old top layer without damaging the substrate. The perfect preparation for the surface to be treated again.

Advantages of air stripping

Typical of air erasers are the constant and precise dosing, low blast pressure and fine abrasive. This is how details are preserved, for example on an antique wooden chair. The big difference with sandblasting is that air erasers don’t use chemicals. Further advantages:

- Fast and efficient cleaning of different surfaces

- Very limited impact and therefore less aggressive than most other methods

- Eco-friendly blasting technology

- Applicable on wood, metal and stone

- Surface ready for new finish immediately

Experts in air stripping

Air erasers are often used on wood and veneers, often on old furniture. Specialist work, that is, because you want to take the best possible care of those items. Quality tools such as a blast pot, gun, medium and compressor are quite an investment. If you are are going to do the job and you choose a cheap variant, the chances of damage to your furniture are high. As experts, we have the right material at HQcoating.

And we also specialise in the perfect finish, with a guaranteed beautiful result. Should air stripping not prove to be the appropriate way to clean or treat your object, our specialists can advise you on other options.

Questions about air erasers? Quote?